Cored Wire

The core-spinning technology is a kind of refining method that has been developed in recent years and is widely used in the technology of modern steel-making feeding wire (adding core wire to steelmaking furnace). Many core wire manufacturers are now promoting this product.

- Grade: Customized according to your needs

- Size: 0.4mm(Wire Thickness)

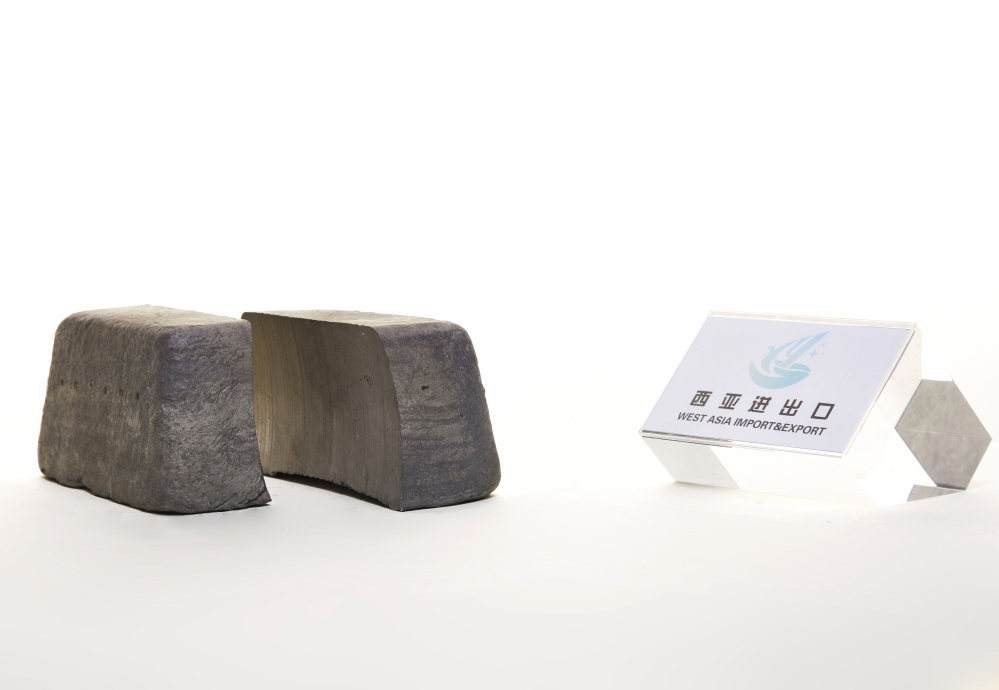

It is made of alloy powder wrapped in strip-shaped steel strip. According to the difference of alloy powder, it can be divided into: silicon-calcium cored wire, silicon-manganese-calcium wire, silicon-calcium-barium wire, barium-aluminum wire, aluminum-calcium wire, calcium-iron wire, pure calcium wire and so on. The winding appearance is similar to a coil, which is different from the cored wire used in the textile industry, and can be customized according to the special requirements of users. It is added to molten steel or iron to make it to a certain particle size, and then packed into composite materials of any length using cold-rolled mild steel strips. The cored wire is composed of steel cladding coated with alloy powder, it is wound on a reel, the coil weight is 100-3000 kg, and the wire diameter is 3-18 mm

Cored wire specification

| Model | Chemical Composition(%) | Wire Diameter (mm) | Wire Thickness (mm) | Wire Weight (g/m) | Powder Weight (g/m) | Uniformity (%) |

| Ca | Ca98 | 13.0 | 0.4 | 170 | 230 | 2.5-5 |

| Sica | Si55 Ca28 | 13.0 | 0.4 | 170 | 230 | 2.5-5 |

| SiCaBa | Si55 Ca15 Ba15 | 13.0 | 0.4 | 170 | 220 | 2.5-5 |

| CaFe | Si55 Ca30 Ba15 | 13.0 | 0.4 | 170 | 215 | 2.5-5 |

| C | 90min | 95min | 98min | |||

Application and characteristics of cored wire

1. Widely used in iron and steel industry and foundry industry. It is beneficial to adjust and control the content of easily oxidized elements and trace elements, can greatly increase the alloy yield, reduce smelting costs, shorten smelting time, and precisely control the composition.

2. Play the role of purifying molten steel and partially changing the nature and shape of inclusions, improving the quality of molten steel and improving the casting state.

3. There are two kinds of cored wires: internal draw type and external release type. The mechanical equipment required for wire feeding is simple and reliable, and the floor space is small, especially the internal draw type cored wire is more suitable for use in narrow and small places.

4. Powder core wire is usually called cored wire, mainly in three aspects: inoculation, out-of-furnace refining, and special element alloying. Fixture performance testing, testing the overall performance and function of welding fixtures.